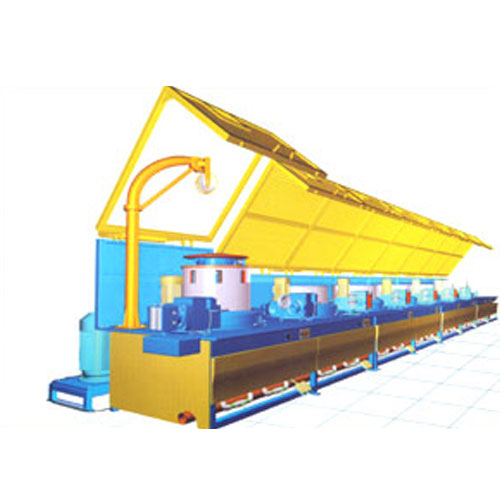

Dry Wire Drawing Machine

Straight Line Wire Drawing Machine

Our manufacturing portfolio offers a complete range of state-of-the-art, high-speed and sturdy Straight Line Wire Drawing Machines (SLM). Our SLM Machines offer high quality and high production drawing of wires with lower operator interference.

Theoretically, there is no limit as far as the wire material or wire diameter is concerned. ASSOMAC has indigenously pioneered the development of the Straight Line Wire Drawing Machine Technology in India. Presently, the available capstan diameters are 250 mm, 300 mm, 400 mm, 450 mm, 500 mm, 550 mm, 610 mm, 660 mm, 760 mm, 900 mm, 1000 mm and 1200 mm for inlet wire diameters from 1.2 mm up to 18 mm. The maxirnum line speed is upto 28 mtrs./sec., depending on the machine and wire size.

These machines provide remarkable drawing performance for Low/Medium/High Carbon Steel Wires, Stainless Steel Wires, special Alloy Steel Wires and Non-Ferrous Alloy Wires.

These machines have a sensor roller between the drum and the next die. When the wire passes in contact with this roller the sensors detect the position of the arm and maintain tension on the wire by regulating the speed of the drums. The drums of these machines are inclined on the vertical axis to effect filling on the drums. Principally, this machine is best suited for the high production of high-quality wires.

Features of Straight Line Machine:

- Machines are built on a modular structure, in combination with blocks and do not require any special foundation.

- Better productivity due to higher drawing speed, twist-free operation & better cooling.

- Easy operation and faster threading.

- High-pressure narrow gap internal water cooling for high-efficiency cooling of wire.

- A high degree of reliability and low downtime due to a lower number of moving parts.

- Much better finished product quality due to gentler handling of the wire during the drawing process (fewer wire deviations, low torsion etc.) as well as optimized wire cooling.

- A highly effective pneumatic braking system in case of emergency.

- Better environmental conditions due to increased dust protection.

- Greater flexibility and lower power consumption due to modern AC drive technology along with an efficient power transmission system.

- PLC-based control with Profibus / Profinet digital communications and fault diagnostic system.

Optional Fitment:

- Stripper Block on finish capstan

- Die less drawing trough Rolling Cassette

- Rotating Die Boxes

- Laser wire diameter measurement system

- Motorized Soap Applicator Die Boxes

- Dust Suction System

- Online Modem based PLC support

Dancer Type Straight Line Machine

This type of Straight Line Machine has the drums on a vertical axis without any incline. The wire transfer happens through two fixed pulleys and one moving pulley mounted on a dancing arm. This dancing arm is either spring-loaded or pneumatic loaded with a sensor to send the feedback signal for synchronization of block speed.

There is a constant length of wire on the drum and the wire from the drawing drum is transferred to the next die through the fixed pulleys and dancer pulley in the inclined plane.

This machine is particularly suitable for wires below 4 mm in diameter and is a necessary requirement for wire sizes below 1.5 mm. Other features, fitments and optional attachments remain the same as offered with the straight line sensor control type machine.

| SLM | DANCER CONTROL | SENSOR CONTROL | ||||||||||

| DRAWING M/C MODEL | ASL - 250 | ASL - 300 | ASL - 400 | ASL - 450 | ASL - 500 | ASL - 550 | ASL - 610 | ASL - 660 | ASL - 760 | ASL - 900 | ASL - 1000 | ASL - 1200 |

| BLOCK SIZE | 250 | 300 | 400 | 450 | 500 | 550 | 610 | 660 | 760 | 900 | 1000 | 1200 |

| Max. INLET WIRE ROD (C=0.80%) | 1.80 | 2.60 | 3.50 | 4.00 | 4.50 | 5.00 | 6.50 | 8.00 | 10.00 | 12.00 | 16.00 | 18.00 |

| (C=0.12%) | 2.20 | 3.00 | 4.00 | 4.50 | 5.00 | 6.00 | 8.00 | 10.00 | 14.00 | 16.00 | 20.00 | 24.00 |

| Min. OUTLET WIRE | 0.38 | 0.50 | 0.60 | 0.80 | 1.20 | 1.40 | 1.60 | 1.80 | 2.50 | 3.00 | 5.00 | 6.00 |

| Max. SPEED (mtr./sec)* | 25 | 25 | 25 | 28 | 24 | 28 | 24 | 18 | 12 | 6 | 7 | 8 |

| Max. POWER (kw) | 5.50 | 11 | 15 | 18.50 | 22 | 30 | 45 | 55 | 75 | 120 | 150 | 180 |

*Max speed is dependant on number of Block, Material Input, Motor Power and other Technical Parameters.

The given speed is just indicative maximum design speed.