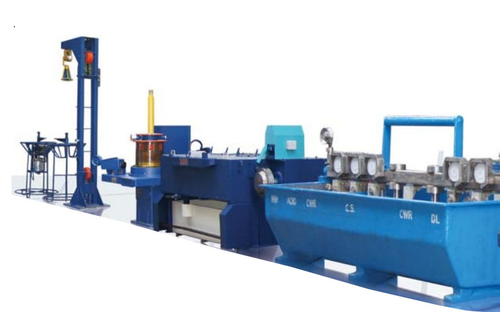

MIG Welding Wire Plant

ASSOMAC offers a high-speed integrated copper coating line for high-speed continuous drawing and Nine copper coating of solid welding wires.

ASSOMAC is entrusted by its honoured customers with the responsibility of providing a modern high-speed, simple-to-operate, low cost and low-downtime machine. We had to go to the drawing board and come up with several offerings to suit customer needs. This line consists of a Pay Off with entanglement sensing arrangement, Pre-Dry Wire Drawing Block, 9 or 11 Dies, 3 or S Spindle, Wet Drawing Machine, FRP / PP Copper Coating Tank with rotating skin pass finishing die, Triple Deck BB Block with killing arrangement and Spooler for Plastic Spools or Bulk Spool. Additionally, Pointing-:um-Threading Machine, Butt Welding Machine, Control Panel and Control Desk are also a part of the complete plant.

Plant Features and options :

- Wet Wire Drawing concept.

- High-Speed, high-efficiency belt drive for sound-less and maintenance-free transmission of power in Wet Drawing Machine.

- Solid Tungsten Carbide drawing cones for high service life and best quality wire finish.

- Copper Coating Tank made out of fibre-reinforced plastic and poly-propylene material with six or seven chambers and material with heating arrangements.

- Cast nylon engineered plastic pulleys for corrosion resistance in the coppering tank.

- Adjustable killing rollers 11 or 13 each in vertical and horizontal planes for proper cast and helix both at BB Block and Spooler.

- Wire accumulation at BB Block for continued working when Spooler stops.

- Pneumatic clamping of spools for faster working at the Spooler.

- Traverse with variable pitch adjustment using A.0 variable drive or variable U hinge traverse.

- The complete plant is controlled by one man using the centralized control station.

- A coating tank with ceramic pulleys and fume enclosing top cover is available optionally.

- Optional high-speed tandem type machine model available specially form 1.00 mm and 1.20 mm wires with all Rotating Dies.

Technical Data :

| Intel Wire Dia | 2.4 - 2.0 mm |

| Finish Wire Dia | 1.6 / 1.2 / 0.8 / 0.6 mm |

| No. of Dies | 1 Dry + 11 Wet + 1 Skin Pass Rotating Die |

| Line Speed* | 8 - 15 mtrs./sec.(Model Dependent) |

| Power Requirement | 10 HP at Pre Drawing Block 60 HP at Wet Drawing 15 HP at BB Block 5 HP at Spooler (Different Spool Diameter Options) |

| Brakes | Pneumatic Disk Brakes on BB Block |

| Drive | Imported Timer Belts & Pulleys, Plain and V-Belts |

| Controls | PLC Controlled or Synchronized A.C. Variable Frequency Drives Panel with Operator Console. |